Ensuring safety in a construction roll-forming shop is of the utmost importance for protecting workers, equipment, and materials. Without exception, when it’s hands against a machine—the machine always wins. Drawing from industry best practices, here are 15 safety measures, each illustrated with an example, to keep workers safe, materials undamaged, and equipment running smoothly and safely throughout the workday:

Comprehensive Training Programs

All operators should undergo thorough training on machine operation, safety protocols, and emergency procedures to minimize accidents.

Example: A new employee receives hands-on training on operating roll-forming, folding, and other machines, ensuring they understand the correct procedures and safety measures before working independently.

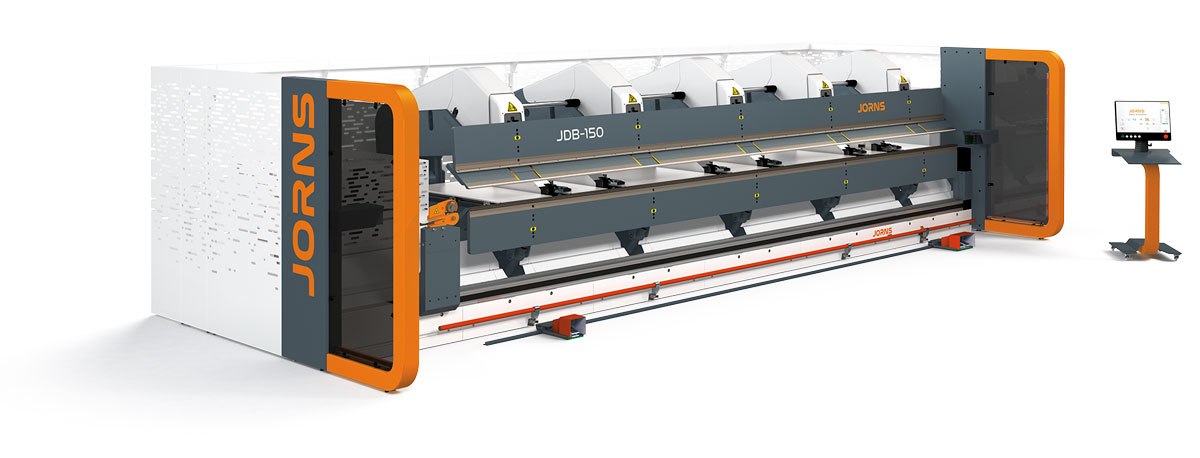

Regular Machine Maintenance

Implementing a routine maintenance schedule helps identify wear and tear, ensuring machines function correctly and safely.

Example: Weekly inspections of roll-forming equipment detect early signs of wear, preventing unexpected breakdowns and potential injuries.

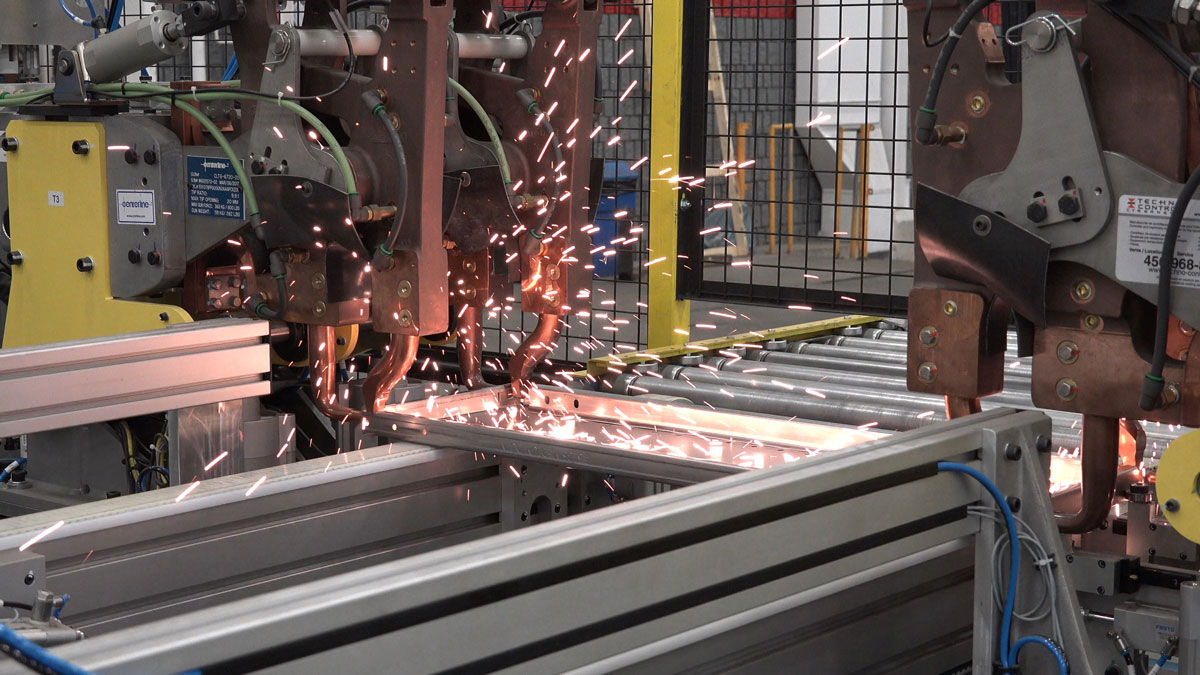

Proper Machine Guarding

Installing guards on moving parts prevents accidental contact, reducing the risk of injuries.

Example: Guarding is installed around the rollers of a forming machine, preventing operators from accidentally placing their hands near moving parts.

Use of Personal Protective Equipment (PPE)

Operators and anyone who handles metal panels and trims should wear appropriate PPE such as safety glasses, gloves, and steel-toe shoes to protect against potential hazards.

Example: Workers wear cut-resistant gloves and safety goggles when handling metal trims, reducing the risk of cuts and eye injuries.

Lockout/Tagout Procedures

Before maintenance or repair, machines should be properly shut down and locked out to prevent accidental startups.

Example: During maintenance, the technician locks out the power supply to the machine, ensuring it can’t be accidentally activated.

Emergency Stop Mechanisms

Machines should be equipped with accessible emergency stop (E-stop) buttons to quickly halt operations in case of emergencies.

Example: An operator notices a malfunction and immediately presses the emergency stop button, preventing potential injury.

Clear Signage and Warnings

Posting visible signs and warnings around hazardous areas keeps safety top-of-mind for all employees.

Example: Warning signs are placed near high-voltage areas, alerting workers to potential electrical hazards.

Proper Material Handling

Using approved lifting devices and techniques when handling heavy materials prevents injuries and equipment damage.

Example: A worker who has been properly trained on the equipment uses a crane or forklift to lift metal coils, reducing the risk of material damage.

Routine Safety Audits

Conducting regular safety audits helps identify potential hazards and ensures compliance with safety standards.

Example: Monthly safety audits reveal a cluttered workspace, prompting a cleanup to prevent tripping hazards.

Adequate Lighting and Ventilation

Ensuring work areas are well-lit and ventilated reduces the risk of accidents and exposure to harmful substances.

Example: Installing additional lighting in dim areas improves visibility, reducing the chance of accidents.

Housekeeping Practices

Maintaining a clean and organized workspace prevents tripping hazards and allows for efficient operations.

Example: Regular cleaning schedules ensure walkways are free of debris, preventing slips and falls.

Proper Electrical Safety

Regularly inspecting electrical components and ensuring machines are properly grounded prevents electrical hazards.

Example: Routine checks identify frayed wires, which are promptly replaced to prevent electrical shocks.

Emergency Preparedness Plans

Having clear procedures for emergencies, including evacuation routes and first-aid protocols, ensures quick and effective responses.

Example: Conducting fire drills familiarizes employees with evacuation procedures, ensuring a quick response during actual emergencies.

Regular Equipment Inspections

Inspecting machines for signs of damage or wear before use ensures they operate safely and efficiently.

Example: Pre-shift inspections detect a loose bolt on a machine, which is tightened before operation to prevent malfunction.

Encouraging a Safety Culture

Promoting open communication about safety concerns and encouraging reporting of hazards fosters a proactive safety environment.

Example: Using a suggestion box allows employees to anonymously report safety concerns, leading to timely interventions.

Safety in a roll-forming shop doesn’t happen by chance—it requires intentional planning, consistent action, and a commitment from everyone. By implementing these safety measures, businesses not only protect their workers, materials and equipment but also improve productivity and morale. From thorough training and proper machine guarding to fostering a proactive safety culture, each step plays a critical role in creating a safer, more efficient workplace. When safety becomes part of the daily routine, it sets the foundation for long-term success and ensures that every worker returns home safely at the end of the day.